Machines

15 different Machines – different Applications !

Boilie-Benz is the oldest boilie-machine manufacturer in the world, by far with the most experience in building boiliemachines. We do not sell just half-devices made from frames with attached wheels or wobbly imitation products. We only sell fully assembled, seriously boilie machines, developed by ourselves, and protected by patents.

Seal of Quality: Our machines are built by using only the best materials, they are completely matured and already have been tried and tested thousands of times. As proof of quality and conformity we have executed the legally required conformity assessment procedure for all of our boiliemachines :

Boiliemachines from “Boilie-Benz” therefore are entitled to carry the required CE label for European Standards !

.

We can offer five different Categories of Boiliemachines :

Cat.3 – for Profis und Specialists (Top-Tip!)

1490.- to 2990.-€ (incl. 19% MwSt.)

Cat.5 – best machines !

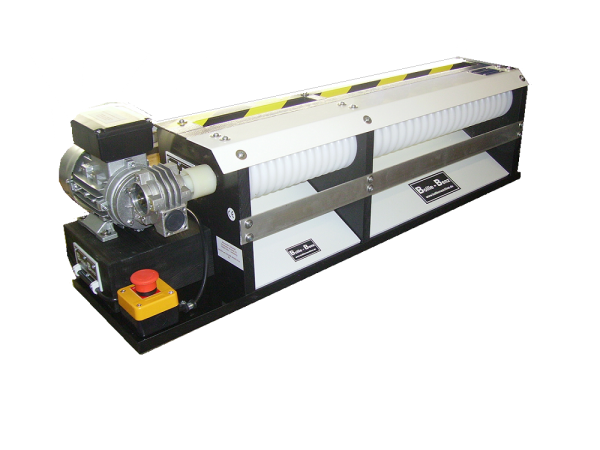

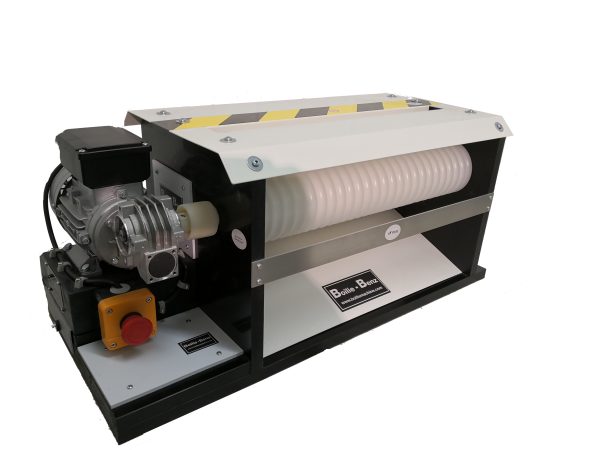

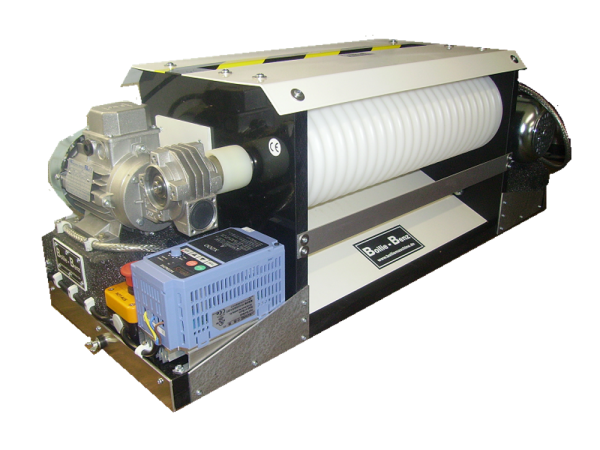

“Business-Benz” and “Big-Benz” Machines

3490.- to 6390.- € (incl. 19% MwSt.)

.

Best roundness is possible by using machines of Cat. 3 and Cat.5 !

Rolls :

very long, full material, for quick productions:

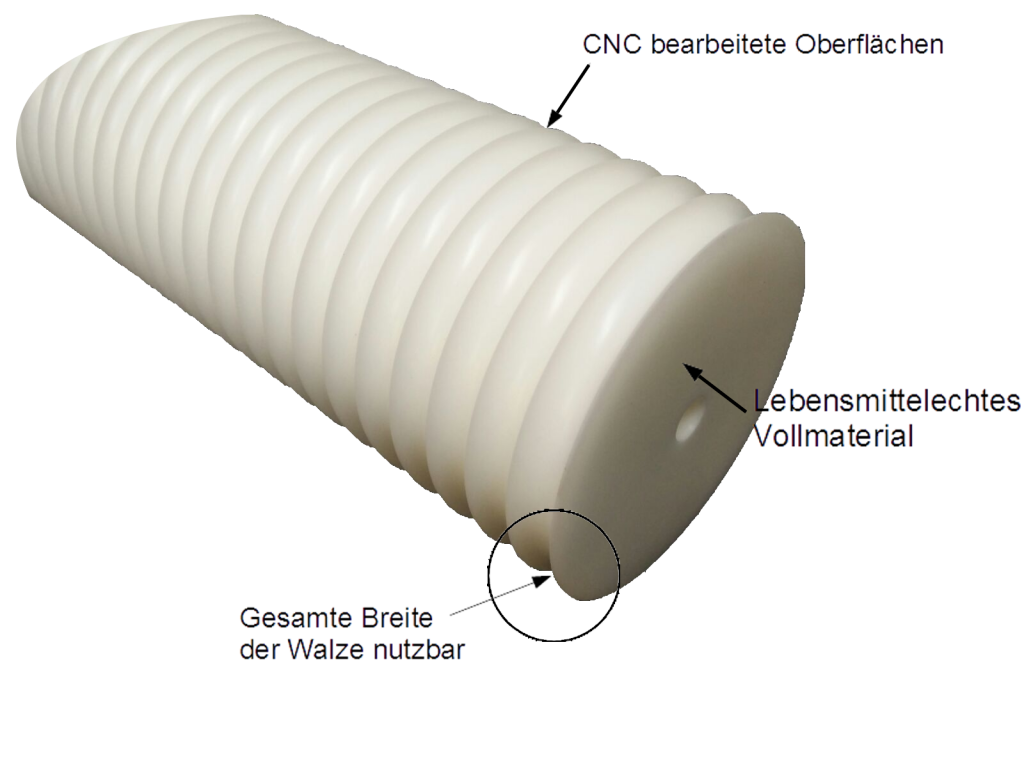

Maximale Präzision

- durch Fertigung mit Fortschrittlicher CNC Technik

Hochwertige Materialien

- Vollmaterial

- lebensmittelecht

Perfekte Voraussetzungen

- volle 48 cm Walzenlänge

- reinigungsfreundliche Oberfläche

Reinigen der Walzen

Das Reinigen unserer Boiliemaschinen geht bei unserem Maschinenaufbau wirklich sehr leicht.

Die Abdeckung muss nicht abgenommen werden und auch sonst muss am Gerät nichts abgeschraubt werden.

Man kommt überall ganz leicht ran – die Reinigung ist ein Kinderspiel und dauert alles in allem nicht länger als etwa zwei Minuten.

Ebenso hier zu sehen : Das Umdrehen der Ablauframpen, ein zusätzlicher Vorteil unserer Maschinen.

Es ermöglicht bei fast allen unserer Modelle ein komfortables und sehr variables Arbeiten !

Unser Wechselmotor-System

Mit dem von uns entwickelten “Wechselmotorsystem” lässt sich Ihre Produktionskette schnell und kostengünstig erweitern.

Eine unserer besten Ideen, die Ihnen hilft viel Zeit zu sparen !

Unten ist ein Video über unser weltweit einzigartiges “Wechsel-Motor-System” (hier bei einer Profi-Maschine mit Frequenzumrichter) zu sehen.

Die Idee entstand bereits Anfang 2001, wir haben sie aber erst später auf einen speziellen Kundenwunsch hin in Serie umgesetzt. Ausprobiert wurde der “Wechselmotor” etwa ab 2oo3, angeboten wird er von uns jetzt seit fast 15 Jahren.

Mittlerweile haben viele Nutzer realisiert, dass das System verglichen mit dem früher üblichen Walzenwechseln weitaus stabiler ist, dass es dazu viel schneller geht, und insgesamt gesehen nur Vorteile bringt.

Da wackelt nichts, da eiert nichts – das passt einfach !

Der Motorwechsel ist ganz leicht, denn wir haben das Wechsel-System sehr einfach aufgebaut.

Man braucht kein Werkzeug, das ganze dauert nicht einmal eine Minute !